Our customers often request a solution for keeping their inventory systems free from over-stocking and spend, but wish to remain scalable during seasons of high demand. The Inventory Management system in Microsoft Dynamics NAV provides a comprehensive functionality that will help control your inventory for increased operational efficiency, improved customer service, reduced inventory and distribution costs.

Item Replenishment Routine Module (IRR) is an extension module to the NAV inventory management system and as such, is built using Microsoft coding principles and deployed within NAV.

The prime purpose of the IRR module is to assist the management of planning parameters on the item card and stock keeping unit. This means that your stock levels are constantly monitored as part of your Inventory Management.

This routine suggests minimum stock and or reordering levels based on historical transactions usage of an item. This helps maintain a lean stock level within the business.

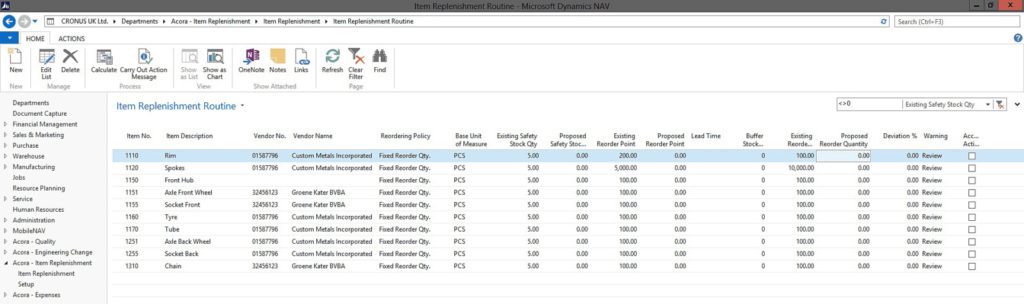

See below a preview of the IRR module & editor (click on the images for full size):

- considers periods of three months from a definable start date

- identifies spikes within a period

- considers buffer stock

- considers lead time for suggestions

- runs for all or selective items

- automatically updates minimum stock levels and reordering point

- these parameters are then used as part of the standard NAV MRP & MPS (Master Planning Scheduling) functions alike

- built on Microsoft coding principles and deployed within NAV object set

Benefits of the IRR module are:

- companies can deal with fluctuating stock holding requirements due to seasonality and or product life cycle

- less surplus stock taking up, storage space and costs

- quick and easy to use allowing the process to be conducted more frequently thus resulting in a more accurate stock holding to actual requirements

- reduce manual data entry and get your goods to market fast